innovative technology for sterilization & disinfection

THE POWER OF ELECTRONS - LIMITLESS POTENTIAL

THE POWER OF ELECTRONS - LIMITLESS POTENTIAL

Applications

Electron beam (E-Beam) treatment is a form of ionizing energy that is characterized by its low penetration and high-dosage rates. The beam – a concentrated, highly charged stream of electrons – is generated by accelerators capable of producing continuous or pulsed beams. As the product/material being sterilized passes the E-Beam, energy from the electrons is absorbed, altering various chemical bonds, damaging the DNA, and destroying the reproductive capabilities of the microorganisms.

Electron beam (E-beam) technology is a non-thermal, chemical-free, food processing technology that is slowly and steadily making a profound change in the quality and safety of foods, food ingredients, and food packaging around the world. E-beam treatment is used to control bacteria in food.

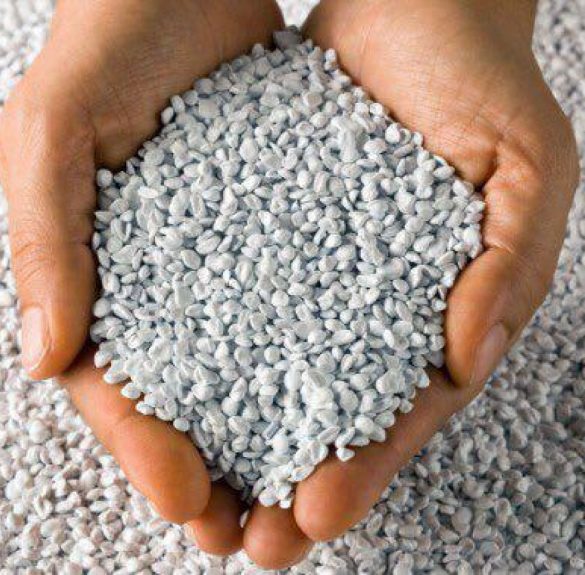

The treatment of seeds with accelerated electrons is a modern, environmentally friendly method that works without any chemical ingredients. Pathogens are effectively and completely destroyed without harming the endosperm and the embryo in the seed.

E-beam crosslinking is energy efficient. Since exposure time of the material to the beam is minimal (seconds), high throughputs are typical. E-beam technology is precisely controlled and the degree of crosslinking is directly related to the level of e-beam exposure.

E-beam processing for medical devices involves the use of high-energy electrons–typically with energies ranging from 3 million to 10 million electron volts (MeV)–for the sterilization of single-use disposables. The electrons are generated by accelerators that operate in a continuous-beam mode.

The use of electron beam to disinfect sewage water is gaining importance. The current problem on environmental health in relation to water pollution insists for the safe disposal of sewage water. In general, sewage water comprises of heterogeneous organic based chemicals as well as pathogens.

Establishing optimal processes for the reuse/recycling of polymeric materials thus remains a worldwide challenge as we enter the new century. Due to the ability of ionizing radiation to alter the structure and properties of bulk polymeric materials, and the fact that it is applicable to essentially all polymer types, irradiation holds promise for impacting the polymer waste problem.

Electron beam curing for inkjet provides a diversity that is needed to stimulate the industry and to take a step towards progress for a healthier environmental future. In today’s world, less means more. With a flexible and compact size and self-shielded vacuum sealed technology, factory footprint is greatly reduced.

The Mini Revolution

Starts HERE

While most materials manufactured for use in sterile health care products are formulated for radiation stability, some materials – certain polypropylenes, for example – experience less breakdown and long-term aging effects as a result of E-Beam’s shorter exposure time. Other benefits include:

- Is simple and easy for automation.

- Is environmentally friendly, as it does not require catalysts and additional chemicals that produce secondary pollutants.

- Operation can be solar powered.

- Low Operating Costs than other competitive technologies.

- Superior Control over the Process.

- Tighter Tolerances.

- Eliminates Limitations in Polymer Compositions, Compounding and Extrusion.

- Eliminates Costly Additives.

- Can Turn E-Beam Off unlike Cobalt Gamma Source.

- Extremely Efficient and Short Treatment Times.

Looking for a reliable scientific partner?

Contact Us

E: contact@pelegol.com